Your business must now be the face of changing technology to succeed and strive in the manufacturing industry. Irrespective of you being a new entrant or a seasoned one, your business can be revolutionized with the help of CNC machining and this will be how you will be set apart from the rest. Your manufacturing processes will get automated, sped up, and more efficient, all while abiding by your budget. High-quality and chiseled customized parts will be available to you within just a blink of your eye.

What is CNC milling machining?

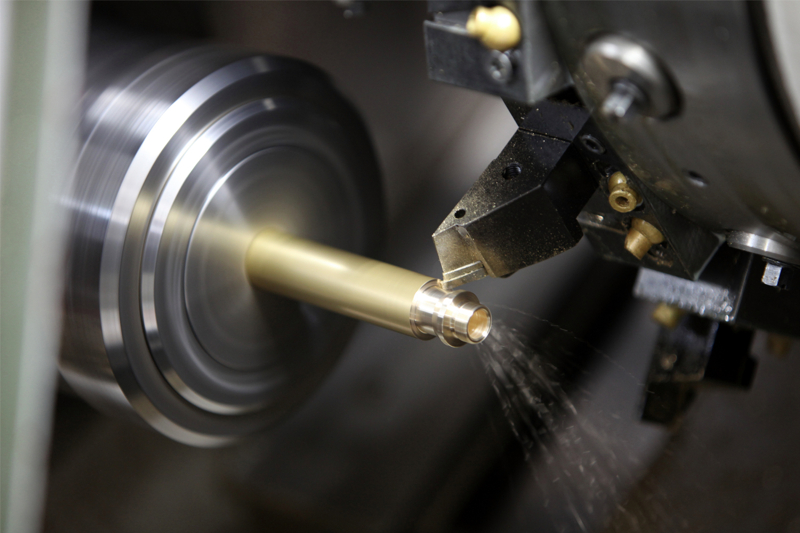

This is the entirely computerized process for employing controls and multi-point tools. This helps in the material removal from the piece and production of the custom machined parts. This process can carve suitable parts from materials as complex as plastic, metals, and even wood. It follows a set of predefined processes like:

- Designing the desired parts in CAD

- Translating the files in CAD to code for machining

- Setting up the CNC machinery

- Producing the machined parts

The CNC milling procedures can be of two types depending on the machines that are getting used.

Horizontal milling machine

The tools in this machine are placed horizontally on their definite axis. They are mostly used for finishing purposes in the already produced parts. The design of the machine is very simple. There is a cutting tool mounted onto an arbour and that moves to help accelerate the finishing process. They have their best ability to carve out complex-most parts. They do not require many operations before producing the parts and can bring forth high surface finishes.

Vertical milling machine

The end milling is done through this machine. The components are very similar to that of the horizontal machine but its axis of function is different. This is much cheaper than horizontal milling and is pretty compact. They are very convenient to use because they provide better visibility while working.

How it is changing the industry?

- Any industrial part can be made using this process.

- They can create precise parts and uniform production is maintained.

- Large-scale production can be initiated.

- A wide variety of materials can be used.

- Higher degrees of round parts can also be created effortlessly.

- Production efficiency is increased and industrial operations get safer.

LOCUS Precision CNC machining is taking over your generic production means and you can now rely on us entirely to get your hands on precisely-crafted industrial parts.