Demolition activities play a crucial role in advancing and improving society. However, they can also create substantial amounts of dust, which can pose risks to both people’s health and the environment. With that in mind, it is of utmost importance to implement efficient BossTek dust suppression measures to safeguard the well-being of workers and nearby communities. In this post, we’ll explore different strategies and techniques that can be employed to effectively control and reduce dust levels during demolition projects.

Understanding the risks

Before delving into dust suppression methods, it’s crucial to understand the risks associated with dust generated in demolition projects. Dust particles can contain hazardous substances such as silica, asbestos, lead, and other potentially harmful materials. Inhaling or ingesting these particles can lead to respiratory issues, allergies, or even severe diseases like lung cancer. Additionally, dust can create visibility problems, impairing workers’ ability to safely operate machinery.

Below is a quick look at some effective solutions you can implement on your site to control dust during demolition activities.

Wet suppression

One of the most efficient methods for dust suppression during demolition is utilizing water. Wet suppression involves spraying water onto the demolition site to capture and suppress dust particles. This technique effectively weighs down the dust, preventing it from becoming airborne. It is crucial to ensure adequate water coverage throughout the demolition area to achieve optimal results.

Dust control agents

Using dust control agents can significantly enhance the effectiveness of your dust suppression system and measures. These chemical products are mixed with water and applied to the demolition site. Dust control agents bind the dust particles together, a process that makes them heavier and less likely to become airborne. It is important to select appropriate agents based on the type and scale of the demolition project to achieve optimal dust control.

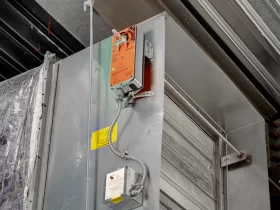

Enclosure and covering

To contain dust within the demolition site, enclosing the area with temporary structures, such as tarps or plastic sheeting, can be highly effective. This prevents dust from dispersing and contaminating the surrounding environment. Additionally, covering loose materials or stockpiles with tarps helps reduce the chances of dust dispersing from these sources.

Vacuum technology

Using industrial-grade vacuum systems during demolition projects can efficiently remove dust particles from the air, preventing them from settling on surfaces or being inhaled. These vacuum systems are equipped with filters capable of capturing small dust particles. Implementing vacuum technology alongside wet suppression techniques can achieve superior dust control results.

Personal protective equipment (PPE)

Equipping workers with appropriate personal protective equipment is essential to safeguarding their health during demolition projects. Dust masks or respirators, goggles, and protective clothing should be provided to minimize the risk of inhaling or coming into contact with harmful dust particles. Regular training on proper PPE usage and maintenance should also be provided to all workers.

Implementing a combination of wet suppression, dust control agents, enclosure, and vacuum technology, and providing proper PPE can significantly reduce dust levels and ensure a safer working environment. By prioritizing dust suppression measures, demolition projects can proceed efficiently while minimizing health risks and environmental impacts.